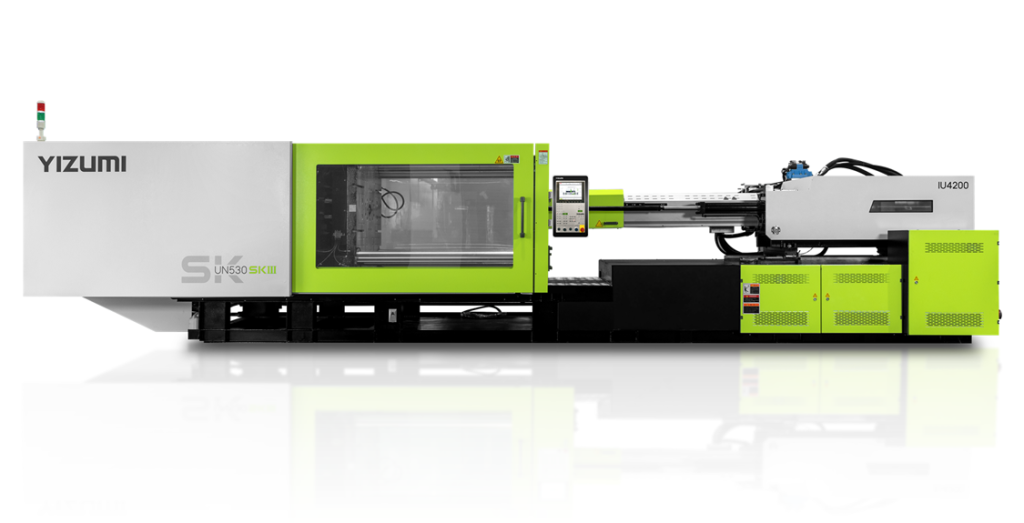

SKIII Model

The SKⅢ series provides efficiency, energy efficiency, stability, and a positive user experience. With its interchangeable SK/A5 platform and ongoing optimizations, it stands out as an ideal option for small to medium-sized machines. Clamping forces range from 900 kN to 10,000 kN.

- Enhanced effectiveness

- Greater stability

- Increased energy efficiency

Clamping Unit

Robust central support for the movable platen structure

– The movable platen, featuring robust central support, reduces platen deformation while ensuring uniform clamping force distribution;

– Employing a lower clamping force minimizes mold cavity deformation, enhances product molding precision, and conserves energy.

Highly durable fixed platen and tail platen design

Tie bar and tie bar nut configuration

Injection Unit

Upgraded injection mechanism

– Enhanced injection linear guide configuration: Decreases motion friction, boosts injection precision, and improves plasticizing efficiency;

– Linear carriage guide with dual-cylinder: Minimizes motion friction resistance for easier handling and servicing;

Newly enhanced cooling system

Refined injection unit

YIZUMI’s fourth-generation energy-efficient servo technology

– The newly designed servo drive system features a one-piece air duct technology, delivering high speeds with low noise;

– Optimized hydraulic circuit design cuts down pressure loss and improves energy efficiency: Utilizes advanced hydraulic principles and valve plate pipeline configurations to minimize oil pressure loss and enhance energy savings.

Control system with added value

– Improved KEBA system.

– Configurable with various modules including AO, AI, DO, DI, and TM to fulfill additional needs.

– Monitors signals from machine-integrated sensors in real time to synchronize corresponding movements, enhancing operational safety.

– Supports a common RS232/485 communication interface, CANOPEN, Ethernet port, temperature compensation sensor connector, and USB port.