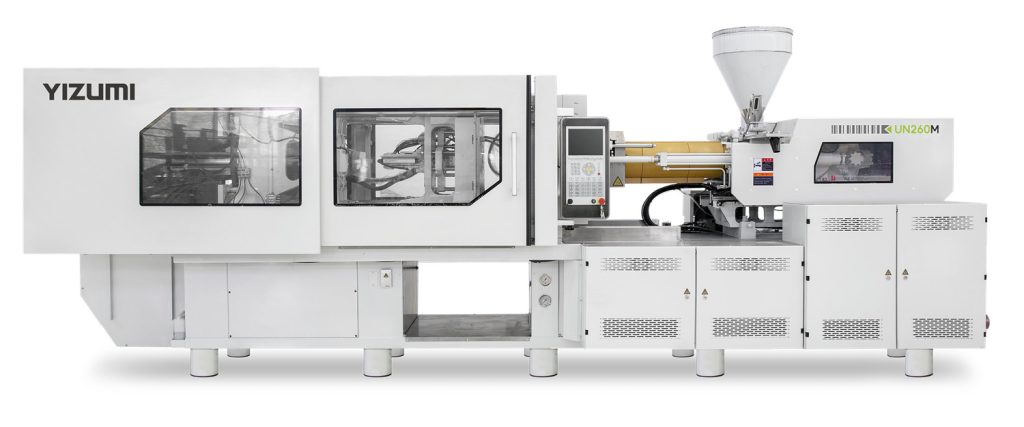

FF-M Model

YIZUMI Medical, focused on the medical sector, provides cutting-edge injection molding solutions and services for a wide range of products, including production consulting, research, development, and large-scale manufacturing. YIZUMI is the partner you can rely on! The clamping forces vary from 1,600 to 3,800 kN.

Features of the FF-M Series Electric Injection Molding Machine:

- High plasticizing efficiency.

- Suitable for clean room production.

- Short dry cycle.

- Clamping Unit: Stable Tie-Bar Free (TBF) design

The platen and tie bars do not make contact, and there is no lubricating oil present on the tie bars, preventing any contamination of the product.

Reduced mechanical friction resistance during the mold opening and closing process leads to less energy loss.

- Injection pressure with closed-loop control.

- Rapid injection: Injection speeds can achieve 120-150mm/s, allowing for a wider range of molding applications to fulfill the requirements of commonly used medical products.

- Unique SDC servo direct control technology.

- The control cycle was reduced from 2-4ms to 0.125ms.

- Injection position, mold opening and closing position-switching position, and control position accuracy are more accurate.

- Intelligent weight control.

- Automatic monitoring and real-time dynamic adjustment of molding process parameters; Effectively reduce the impact of external factors on the molding process, such as mold temperature, raw material properties, etc., to improve the stability of the process.